Envirograf Cavity Barrier Range

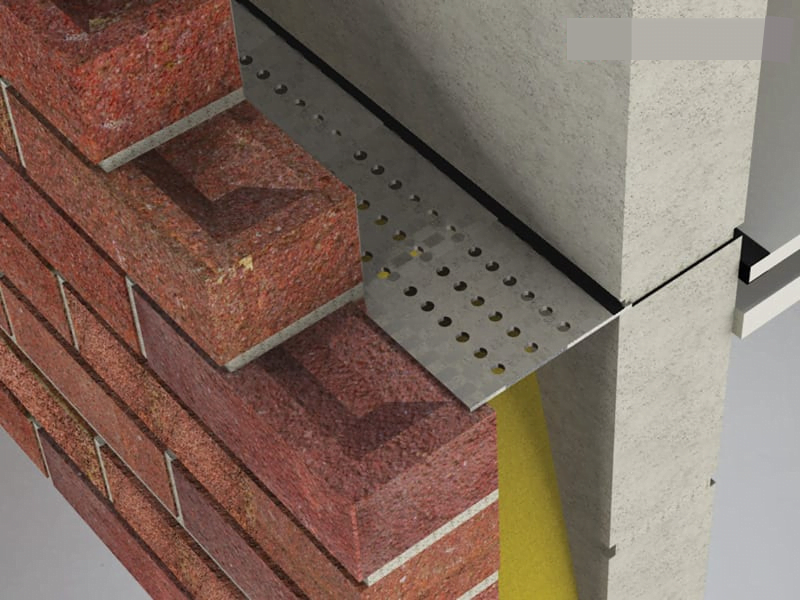

WB

- A flexible foiled barrier ( WB & VWB ) designed to fix across into inner and outer course of brick to block or block to block, held in the mortar joint.

VWB

- This is the same barrier as WB but with ventilation and moisture holes which house a water resistant, rubberised intumescent material which expands in a fire sealing off all holes.

WBS

- The WBS Cavity Barrier is a flexible fire proof sponge which is fixed in a horizontal or vertical position in a brick/block cavity. The WBS has unique self spring properties and is fixed into the cavity by simply pressing the seal into place. The barrier must always be made 10mm wider than the cavity.

VWBS

- This is the same barrier as WBS, However VWBS is for horizontal use only.

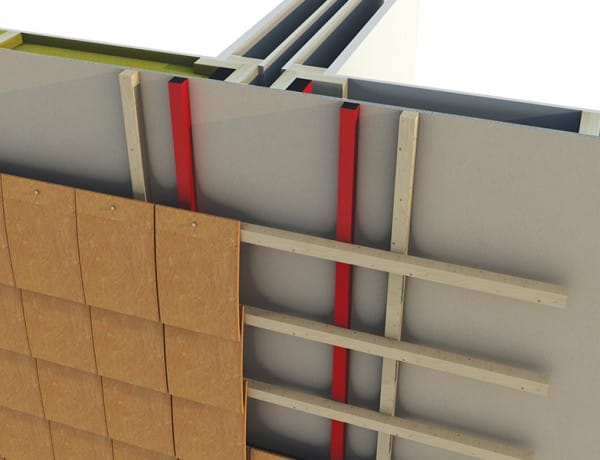

Rainscreen Barrier

- This barrier comes in 3 types, giving complete fire and smoke sealing. A lightweight barrier to lay over and under all types of insulation materials. They are made of the same materials as WB and VWB Range

RS/WB/W | RS/VWB/W | RS/WB/CV/W

- Are made to suit a cavity up to 250mm. They have a 30mm up stand on the back edge with metal washers for screw or nail fixing to concrete, brick, block, cement board, etc

RS/WB/B | RS/VWB/B | RS/WB/CV/B

- This is a similar barrier as RS/WB/W Range, but can be made up to 400mm wide.

RSM Range

- The new RSM range has been especially designed to offer excellent passive fire protection for rainscreen and other types of cladding.

- RSM Range vertical or horizontal use with a robust material covering, completely water resistant.

- RSM/A – RSM/A with intumescent holes to give ventilation & allow moisture through. Option 1 hole ref A 2 holes Ref B

- RSM/I – RSM/I With intumescent in the front face which expands up 50mm so a ventilation gap from 20mm to 50mm can be left.

CV Cavity Strip Barrier

- The Envirograf flexible strip range barrier is a thin flexible PVC & foiled clad intumescent material with a self adhesive backing tape for adhering to the wall, additional fixing can be done by using staples, nails or screws. The seals can be cut to any length with a joint sleeve supplied for sealing off the ends. A strip form of high expansion intumescent with medium pressure to lock against the internal side of the external wall in a fire giving full fire protection without affecting the outer wall. A quick and easy method of application and fixing. The strips are in a blue plastic sleeving robust enough to stop any damage by water or insect/animals or when fixing. Can be sleeved in other colours (White, Black or Red).

FB/TS Cavity Barrier

- Especially designed for timber framed buildings. All the products in this range have been tested according to the appropriate fire test requirements in fully accredited test houses in the UK and Europe, and offer excellent fire ratings, fully satisfying UK Building & European Regulations

Not available to purchase online, please CONTACT US

For sizing , specifications & Requirements CONTACT US

IMPORTANT INFORMATION ON PURCHASING OF PASSIVE FIRE PROTECTION PRODUCTS NOTICE:

The information displayed about the products on this website is to be used for guidance ONLY. We advise that all customers contact our technical department to obtain a free no obligation specification and quotation before purchasing goods directly from the website.

Please be aware that any negligence caused by failure to obtain the relevant advice, or availment of our specification and estimation service, will absolve International Passive Fire Ltd from any liability should Passive Fire Protection Products prepared, or used, by the purchaser, or any other parties, result in damage to property or human life, or for any monetary costs incurred due to incorrect usage.